Running a vessel means you deal with a lot of moving parts every single day. One of the most significant pieces of machinery you depend on is your cargo oil pump turbine. If it doesn’t run well, your whole operation slows down. You deal with higher fuel use, slower loading and unloading, and more stress on your crew. The good news? You can keep it efficient with a few simple habits.

In this guide, you’ll walk through easy ways to understand, manage, and improve the performance of your turbine and pump system. Nothing too technical. Just clear steps you can use right away.

Why Understanding Your Cargo Oil Pump Turbine Matters

You must understand the mechanism of your cargo oil pump turbine to ensure your vessel operates smoothly. The turbine contains steam, which rotates and drives the pump. A well-coordinated movement of the turbine and the pump results in improved flow, speed, and control of the oil in your tank. You also minimise the chances of damaging components such as the valve, bearing, and other minor parts within the system.

When the turbine struggles, everything feels slow. You lose time, your tanker works harder, and you spend more on repairs. So learning the basics helps you spot problems fast. This also keeps your operations safe, steady, and reliable. And that’s what every vessel owner wants.

Key Components in a Cargo Oil Pump Turbine System

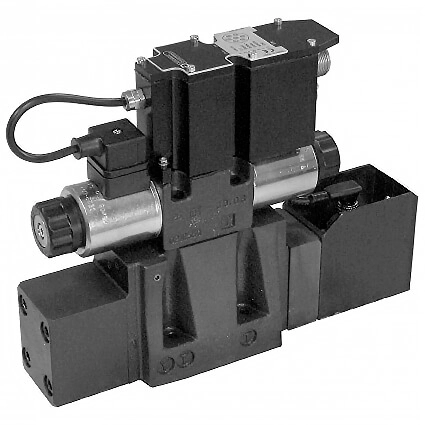

Your turbine system is a system that functions as a whole, and the parts support one another. Their main elements include the turbine, pump, valve, bearing, electrical components, and the control unit, which assist in controlling the flow and temperature. When one component is not functioning correctly, the entire mechanism is affected.

How Each Component Affects Efficiency

Even something as small as a stuck valve or a worn bearing can significantly impact your entire operation. When parts rotate well, the system runs smoothly. However, when they struggle, the turbine uses more steam, the pump slows down, and the flow is lost. That means you burn more fuel and your machinery works harder than it should.

Keeping each part in good shape keeps your cargo oil pump turbine system efficient. This also helps you avoid sudden shutdowns, which everyone wants to avoid.

Factors to Consider When Choosing or Upgrading Your COPT

If you’re considering choosing or upgrading a COPT, always consider the factors that determine the right one. Every tanker has different needs. Your vessel size, daily supply needs, and normal operating speed all matter when selecting a system.

Look at the specifications of every product. Check if the drive works well for your machinery. See if the system matches your tanker’s temperature and steam requirements. Also, check if the parts fit your engine room layout. A good match helps you operate your cargo oil pumps more effectively and provides a more efficient solution.

When you choose carefully, you save time and money. You also reduce stress for your crew.

How to Operate Your Pump and Turbine More Efficiently

You can run your turbine and pump more smoothly when you manage a few simple things. First, always check the steam supply. When the steam flow remains steady, the turbine rotates more efficiently, resulting in a cleaner and smoother cycle. You also want to keep an eye on speed and temperature. When both remain within the right range, the system remains safe and efficient.

Good control also helps. When you adjust the settings with care, you avoid sudden changes in flow. This protects your tank, valves, and other parts.

Managing the Tank and Flow for Better Performance

Sometimes, small changes make a big difference. When you manage the tank level effectively, you help your pump operate at the correct pressure. This keeps your turbine from working too hard. You also help your system stay stable, even during long operations worldwide. This leads to better performance and more efficient flow through your vessel.

Common Issues That Affect Turbine Efficiency and How to Fix Them

Every vessel deals with trouble now and then. Some of the most common issues include steam supply problems, changes in temperature, bearing wear, and electrical concerns. When these things build up, your turbine slows down. You also risk sudden stops or high repair costs.

You can fix most of these issues early on by checking the small details. Inspect the bearings to see if they exhibit any wear. Make sure the valves open and close well. Watch for steam leaks. Observe the temperature and listen for unusual sounds. When you catch things early, you protect your equipment and keep your tanker safe.

Maintenance Practices to Keep Your Cargo Oil Pump Turbine Reliable

Good maintenance gives you the best performance. You don’t need anything fancy. Just simple checks that you do often. Look at the valves, bearings, electrical lines, and temperature control. Ensure each part rotates smoothly and remains clean.

Oil each component when needed and clean the pump room. When you do these checks, you make your systems reliable. You also help your vessel operate smoothly in various conditions and during extended marine jobs.

Explore Reliable COPT Products for Your Vessel

If you want better performance from your cargo oil pump turbine, you also need the right products. The right COPT model helps your vessel run smoother, safer, and more efficiently. At K-Marine, we support vessel owners by offering dependable options that cater to various tanker needs.

Here are some of the COPT models we work with:

Shinko RX0

A compact and steady option that works well for vessels that need smooth and stable pumping. It gives you reliable speed, simple control, and strong performance for daily operations.

Shinko RX1

A stronger model for tankers that need more power. It supports better flow, cleaner rotation, and better handling during longer jobs. You get a good balance between performance and efficiency.

Shinko RX2-2

A heavy-duty choice for tankers with bigger pumping requirements. It manages pressure well, supports steady flow, and keeps up during continuous operations. It’s built for vessels that need strong and reliable machinery.

If you want to see how we handle COPT work in real situations, you can check these guides:

- See our overhaul work here:

https://kmarine.com.sg/wp-content/uploads/2058JR-SA-CAPRICORN-COPT-NO.-3-OVERHAUL-AFLOAT-OUTSTATION.pdf - See our refurbishment work here:

https://kmarine.com.sg/wp-content/uploads/2111JR-GALUNGGUNG-COPT-NO.-3-REFURBISHMENT.pdf

Final Thoughts

Your cargo oil pump turbine plays a big part in your vessel’s performance. The more you understand how it operates and how to take care of all its components, the more efficiently you will operate, have a safer work period, and experience fewer headaches in the future. This is by making small steps day after day to ensure that you take care of your machinery and also make your crew comfortable as they work.

If you want a reliable marine engineering team to help maintain, fix, or optimise your cargo oil pump turbine, we at K-Marine are here to support your vessel. We give you practical solutions that help you operate safely and efficiently.