When you run a vessel or work with a tanker, you know how much you rely on a cargo oil pump turbine. It helps you move oil from the tank to where it needs to go. It keeps your marine operations smooth, steady, and safe. However, when something goes wrong with the pump or turbine, the entire process slows down. You also deal with stress, delays, and high costs you don’t want.

In this guide, you’ll learn the common issues that show up in a cargo oil pump turbine system and how marine engineers fix each one. We will make it easy so you can understand what is going on with your machinery, even if you are not an engineer.

What a Cargo Oil Pump Turbine Does on a Vessel

A cargo oil pump turbine, or COPT, helps you move or transfer cargo oil from tank to tank or tank to shore. It uses steam, flow, and speed to keep things moving. The pump and turbine work together to ensure your vessel handles cargo without issues.

You’ll see COPTs on many tankers because they help you unload oil fast and safely. The system also allows you to control the flow rate, pressure, and temperature when operating the machinery. The smallest detail is significant, as a broken part can significantly impact the entire process. Understanding the mechanism of a pump and turbine, you can identify problems at the initial stage and maintain your ship in proper condition.

Common Cargo Oil Pump Turbine Problems You May See

The cargo oil pump turbine handles heavy work every day. As a result, issues sometimes arise. Here are the most common problems that marine engineers typically encounter.

1. Low or Unsteady Flow Rate

If the flow rate drops, you’ll feel it right away. The pump won’t move oil fast enough. This issue often arises from valve trouble, inadequate pressure, or an obstruction in the tank line. When the flow slows down, your whole unloading job takes longer.

2. High Temperature or Heat Changes

When the turbine gets too hot, you know something’s wrong. Heat affects the speed and control of the unit. Often, the problem originates from steam issues, inadequate lubrication, or a worn-out component. If you ignore it, the machinery suffers.

3. Shaft, Seal, or Bearing Wear

The shaft rotates at high speed. If the seal or bearings wear out, you’ll hear unusual sounds or notice oil leaks. This affects the pump and turbine, and may lead to more significant problems if left unaddressed.

4. Steam or Pressure Drop

A cargo oil pump turbine requires sufficient steam pressure to function properly. If the pressure falls, the turbine slows down or struggles to rotate. This reduces the flow rate and interrupts your operations. You may also feel shaking or see unstable movement.

5. Electrical or Control Issues

Sometimes the electrical side causes trouble. The system can be compromised by faulty control panels, poor wiring, or sensors that fail to read the appropriate parameters. You will require mechanical and electrical balance to operate the turbine effectively.

How Marine Engineers Fix These COPT Problems

Marine engineers follow precise steps to identify and resolve issues. They follow a method that keeps the vessel safe while restoring performance.

1. System Checks

Engineers check the complete cargo oil pump turbine system. They examine the flow, temperature, pressure, and all mechanical components. They also test the valves, control lines, and tank connections. These checks help them find the cause fast.

2. Repair or Replace Worn Parts

After the engineers have identified the problem, they either fix or replace the component that has caused the issue. This can be the shaft, bearings, seals, valves or turbine blades. They also clean dirt and residue that affects the flow and speed.

3. Recalibration and Testing

After repairs, engineers test the turbine and pump to ensure everything works properly. They adjust control settings, check parameters, and bring the system back to an efficient level. They make sure the machinery meets the operational demands of your vessel.

4. Improving Long-Term Performance

Engineers give tips that help you prevent issues. This includes checking the steam supply, observing the flow rate, cleaning parts, and monitoring the temperature. By doing this, you help increase safety and reduce downtime.

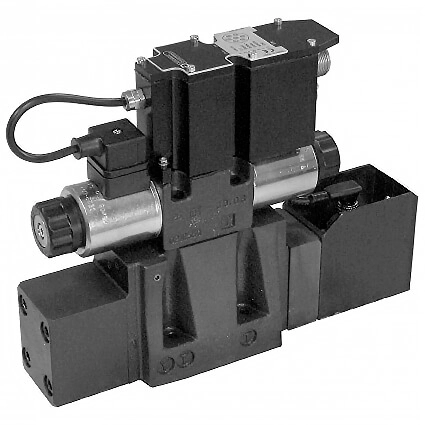

Cargo Oil Pump Turbine Options We Offer

Here at K-Marine, we help vessel owners select the ideal cargo oil pump turbine for their specific needs. We offer strong and tested units such as:

Each model supports fast transfer, smooth handling, and high efficiency. We ensure you receive the right system tailored to your vessel type and cargo requirements.

To see how we handle real COPT projects, you can review some of our recent work. We’ve shared a few case jobs so you can get a clear look at how we repair, overhaul, and restore cargo oil pump turbine systems. You can view them here:

- 2058JR-SA-Capricorn COPT No. 3 Overhaul Afloat Outstation

https://kmarine.com.sg/wp-content/uploads/2058JR-SA-CAPRICORN-COPT-NO.-3-OVERHAUL-AFLOAT-OUTSTATION.pdf - 2111JR-Galunggung COPT No. 3 Refurbishment

https://kmarine.com.sg/wp-content/uploads/2111JR-GALUNGGUNG-COPT-NO.-3-REFURBISHMENT.pdf

Keep Your COPT in Good Shape

To ensure your cargo oil pump turbine remains efficient, monitor your control settings, check the pressure, and listen for unusual sounds—clean dirt from the tank lines and valves. Follow the safe installation steps and inspect the parts regularly. When you maintain the machinery, your vessel handles cargo more efficiently and unloads faster.

Need Help With Your Cargo Oil Pump Turbine? At K-Marine, we take pride in ensuring that ship owners maintain their systems safely and efficiently. We will be happy to assist you with installation, repair, and general inspection. We will maintain your ship in a good state and ensure your cargo business is safe.