Why Marine Systems Rely on Precision Control

Marine engineers must be exact, as it’s necessary for their work. Cranes, winches, and hatch covers on today’s marine vehicles depend greatly on hydraulic control. For these systems to function well and remain safe, fluid flow and pressure must always be controlled accurately.

Steering and handling the hydraulic fluid pressure in the system is done through a directional control valve block. Managing fluid flow through the circuits helps operate equipment steadily when dealing with challenging situations at sea.

What Is a Directional Control Valve Block, Anyway?

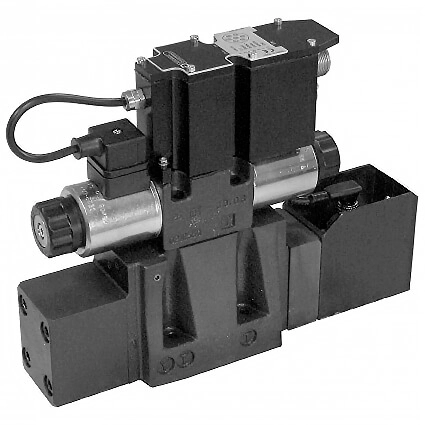

In hydraulics, a directional control valve block, also known as a valve block, regulates the movement of fluid within the system. It sends pressurised fluid to different areas of the system using internal items, such as spools, cartridges, or check valves.

Depending on the application, valve blocks may come in different configurations:

- Manual valve blocks use levers for direct human control.

- Solenoid-operated blocks use electrically actuated coils to move the internal valves.

- Spring-loaded designs automatically return the valve to a default position when inactive.

Each configuration is selected based on the vessel’s hydraulic system needs, balancing performance, responsiveness, and control logic.

How Directional Valve Blocks Work in Marine Vessels

Directional valve blocks make it possible for hydraulic circuits to power equipment such as steering systems, hatch covers, capstans, and cranes in marine areas. To understand, let’s look at how they function.

- Directing Flow from Pump to Cylinder or Motor: Pressurised fluid from a hydraulic pump enters the valve block. The valve then routes this fluid through various ports—typically labelled P (pressure), A & B (actuator ports), and T (tank/return).

- Managing Valve Positions: Valve blocks may offer three positions: extend, retract, and neutral (or central). A closed centre valve, for example, blocks all ports in the neutral position, holding the actuator in place.

- Operating Cylinders: A double-acting cylinder relies on the valve block to pass fluids between ports A and B to achieve the movements of the piston. Single-acting cylinders have fluid flow in one direction, and the return movement is helped either by gravity or a spring.

- Maintaining and Releasing Pressure: As soon as the action is completed, the fluid returns to the tank and pressure is released so the system and its components can reset.

The directional valve block ensures that hydraulic devices on the vessel function seamlessly and move according to the programme.

Standard Components You’ll Find Inside the Block

Several essential components work together inside a directional valve block to control flow and pressure. These include:

- Spools: Move within the block to open or close flow paths.

- Cartridges: Compact, replaceable valve elements that handle flow control.

- Springs: Provide return action in manual or spring-loaded designs.

- Solenoids: Electrical coils that actuate valves remotely.

- Manual Levers: Enable human control where automation isn’t required.

- Check Valves: Prevent backflow and ensure one-way fluid movement.

- Relief Valves: Protect the system from overpressure.

Other aspects to pay attention to in design are psi ratings, sturdy internal gears, and excellent fittings and hoses that give leak-proof results.

The Role of Directional Valve Blocks in Hydraulic Control

Onboard ships, precise hydraulic control is critical to performance and safety. A directional control valve block enables:

- Accurate Position Control: It sends fluid to move a piston or cylinder to a specific position and holds it under pressure.

- Extension and Retraction: It controls how hydraulic cylinders extend and retract, depending on whether fluid is sent to ports A or B.

- Reservoir and Return Function: Once the function is completed, the hydraulic fluid returns to the tank or reservoir; this way, the system is ready for the following circuit.

Closed-loop control helps regulate the flow under any load and operating conditions.

Selecting the Right Product for Your Marine System

Not all directional valve blocks are created equal. When choosing a product for your marine vessel, consider the following factors:

- Load Requirements: What kind of force or torque does the system need to manage?

- Operating Pressure: Ensure compatibility with the system’s maximum pressure rating.

- System Design: Consider how the valve fits into the existing hydraulic circuit.

- Flow Rate: A mismatch can cause performance issues or even damage equipment.

- Brand and Replacement Needs: Look for a suitable, durable block from a reputable brand that offers replacement components for future maintenance.

At K-Marine, we make sure to provide dependable, standard-approved products for use in the marine industry. We assist customers in picking out the right valve block for their use case to guarantee it performs for a long time.

Why the Directional Control Valve Block Matters

The directional control valve block is crucial to the control process in marine hydraulic systems, rather than being a peripheral element. It ensures that fluids, pressure, and placement work smoothly in different systems throughout the car.

Without hydraulics, the fluid couldn’t be sent where it was needed, causing system issues and equipment failure.

Not sure about which valve block to buy? We are ready to help you. If you are keen to learn more about our hydraulic products or get advice for your marine vessel, simply contact us and let K-Marine guide you all the way.