Every ship needs a reliable way to handle its anchor, and this is where the anchor windlass hydraulic motor steps in as the unsung hero of marine operations. Think of it as the muscle that makes handling heavy anchors feel like lifting a feather. Ships of all sizes rely on these powerful systems to raise and lower anchors smoothly, keeping vessels secure in any waters.

From small fishing boats to massive cargo ships, the anchor windlass serves as the backbone of safe anchoring operations, making it an essential piece of marine equipment that every sailor should understand.

What is an Anchor Windlass Hydraulic Motor?

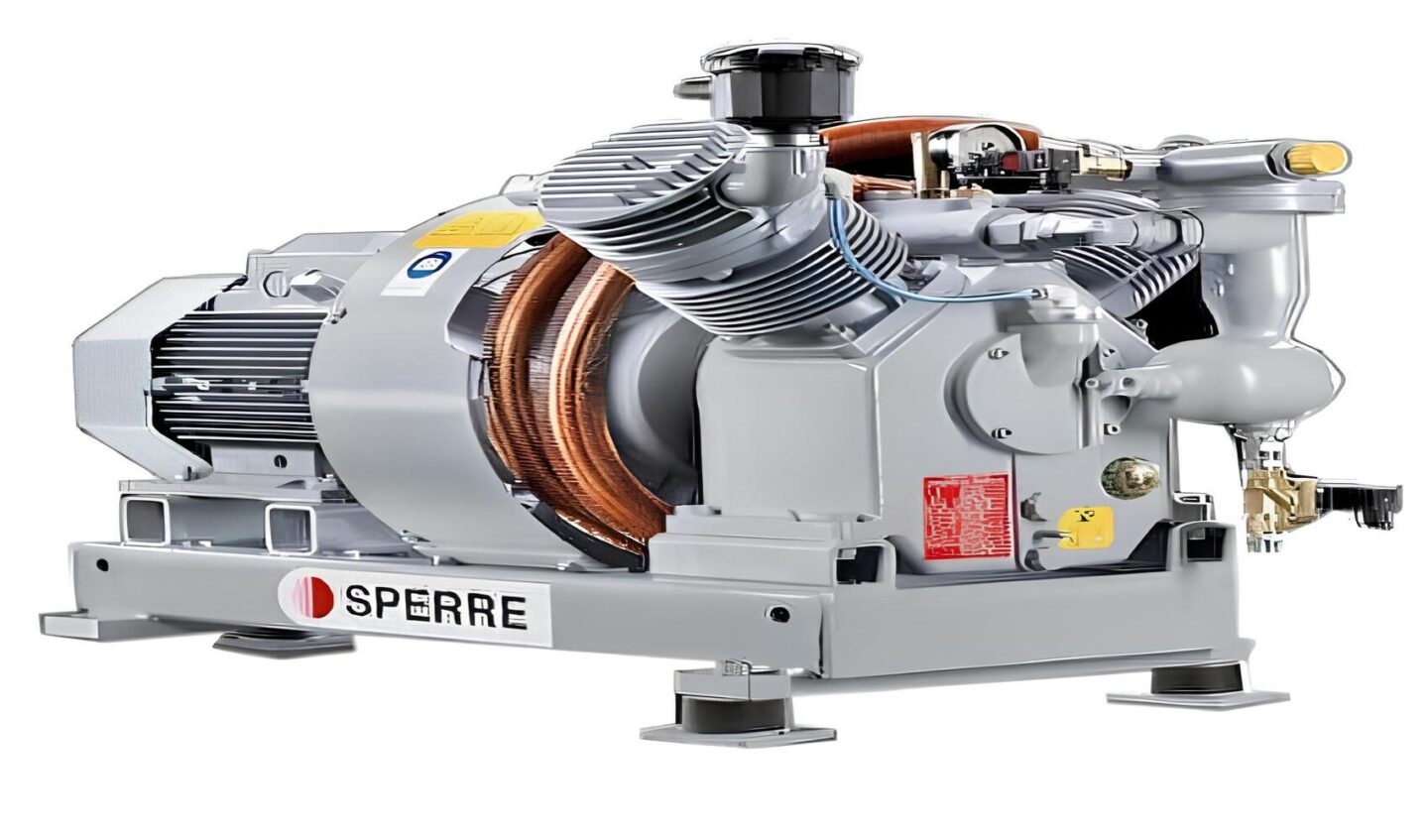

The anchor windlass works like a super-powered winch designed specifically for ships. This marine powerhouse combines a strong motor with a clever system of gears and wheels to handle heavy anchor chains. The hydraulic motor provides the main driving force, converting fluid power into mechanical energy to move those massive anchors.

Picture it as the heart of the anchoring system, pumping hydraulic fluid to create the force needed to lift tons of metal from the seabed. Modern ships rely on these robust machines to make anchor handling safer and more efficient.

Classification of Anchor Windlasses: Vertical vs. Horizontal Systems

Ship designers choose between vertical and horizontal windlasses based on deck space and operational needs. Vertical windlasses stand upright, taking up less deck space but requiring more height clearance. Horizontal systems lie flat along the deck, spreading out rather than up.

Each type comes with its own gearbox setup and chainwheel design. The choice affects how the chain flows, how much torque the system can handle, and where sailors can position themselves during operation. Smart ship designers pick the style that best fits their vessel’s layout and crew needs.

Key Components of an Anchor Windlass Hydraulic Motor System

Every anchor windlass relies on several crucial parts working together seamlessly. The gypsy (also called the wildcat) grips and guides the anchor chain, while the drum stores extra rope or chain. The chain stopper keeps everything secure when the system isn’t moving.

Inside the housing, bearings support the main shaft, while the clutch allows sailors to engage or disengage the drive. The hydraulic power unit serves as the system’s engine, providing the muscle to move these heavy components. Each part plays a vital role in creating a reliable anchoring system.

How Does an Anchor Windlass Hydraulic Motor Operate?

When sailors need to lift the anchor, they start by engaging the hydraulic system. Pressurised fluid flows through the motor, creating rotational force that turns the gypsy. As the gypsy spins, it pulls up the anchor chain link by link.

The system includes controls that let operators adjust the speed and power based on conditions. Modern windlasses often feature remote controls, letting sailors operate the system from different spots on the ship. The whole process runs smoothly thanks to careful engineering and powerful hydraulic components.

Powering an Anchor Windlass: Electric or Hydraulic?

Ships face a key choice between electric and hydraulic windlass systems. Hydraulic systems excel in wet conditions and can deliver more power when needed. They resist corrosion better than electric alternatives and handle heavy loads with ease. Electric systems offer simpler installation but might struggle in harsh marine environments. The choice often depends on the ship’s size, power available, and typical operating conditions. Most large vessels prefer hydraulic systems for their reliability and raw power-handling capabilities.

Working Load and Maximum Pull: Understanding Capacity and Safety

Every windlass comes with specific ratings for working load and maximum pull capacity. These numbers tell operators how much weight the system can safely handle during normal use and emergency situations. Factors like chain size, anchor weight, and water depth affect the actual loads the system faces.

Smart operators always check these ratings and never exceed them. The brake system must handle these loads too, providing reliable stopping power when needed. Using the right chain size and maintaining proper tension helps prevent overload situations.

When to Seek Expert Help: K-Marine’s Role in Marine Engineering

Even well-maintained windlass systems sometimes need professional attention. Warning signs include unusual noises, slow operation, or fluid leaks. K-Marine specialists bring deep experience in fixing these complex systems. We understand how each component should work and can spot potential problems before they become serious. Regular maintenance by qualified technicians helps prevent unexpected breakdowns and keeps systems running smoothly. After all, smart ship operators build relationships with marine experts who understand their equipment.

Conclusion: Ensuring a Reliable Anchor Windlass System

A well-maintained anchor windlass keeps ships safe and crews confident. Regular checks of all components, from the gear system to the brake assembly, prevent costly failures. Smart operators follow maintenance schedules and address small issues before they grow. When questions arise, K-Marine stands ready to help with expert support and service. Taking care of these crucial systems protects both vessels and the people who rely on them. Safe anchoring starts with a properly maintained windlass system.