You’re all set to sail—systems checked, crew ready, route mapped. But when you hit the start button, silence. No engine rumble. Just an alert blinking on the panel. Could it be the starting air compressor?

The starting air system has an essential function in marine engines particularly within large vessels. With no compressed air supply the diesel engine becomes unable to begin its operation. High-pressure air delivery to start the engine depends on the combination of air compressors along with receivers and valves and pipelines. The complete functioning of your operation becomes impossible when starting air system failure occurs.

Let’s break down why this happens and what you can do about it.

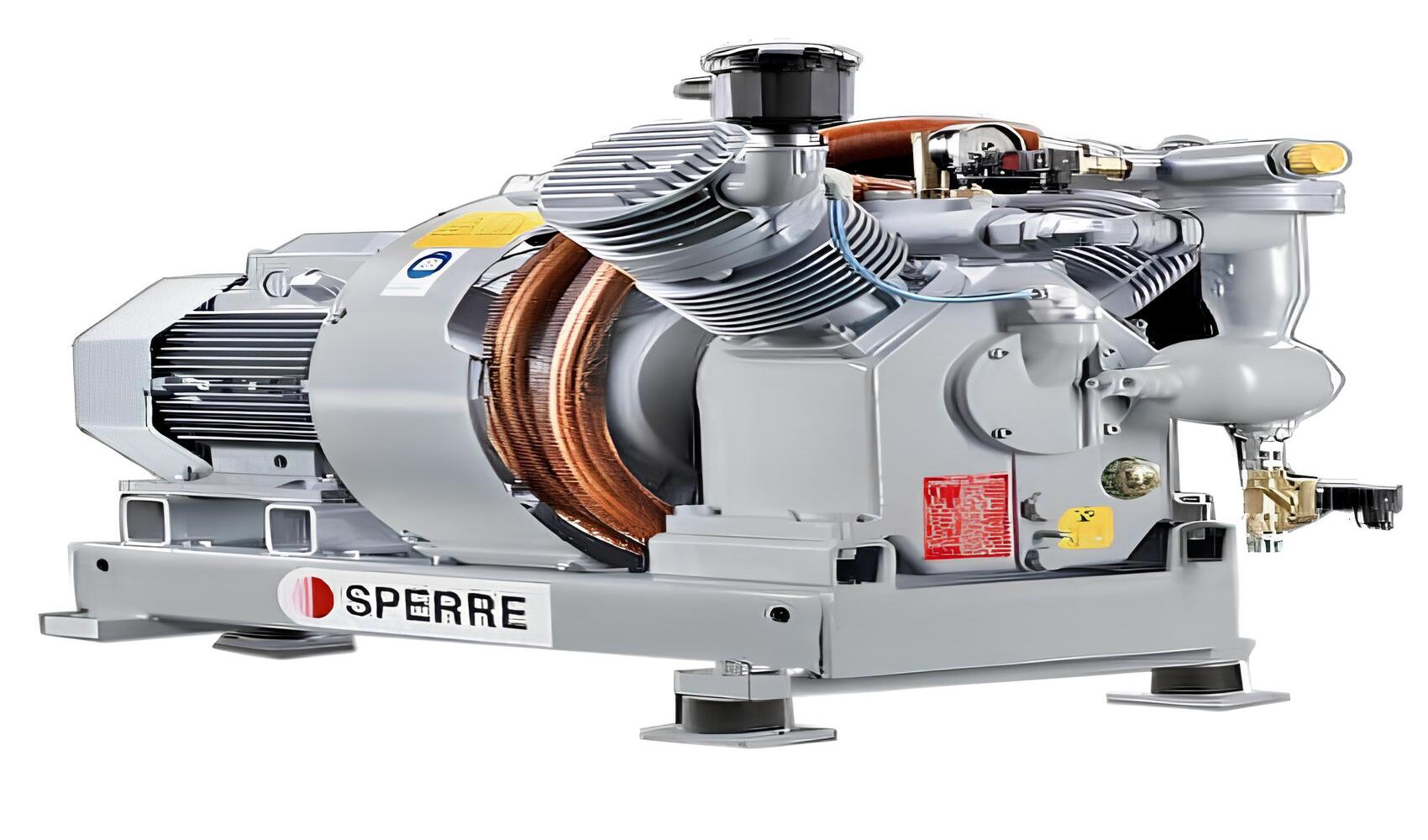

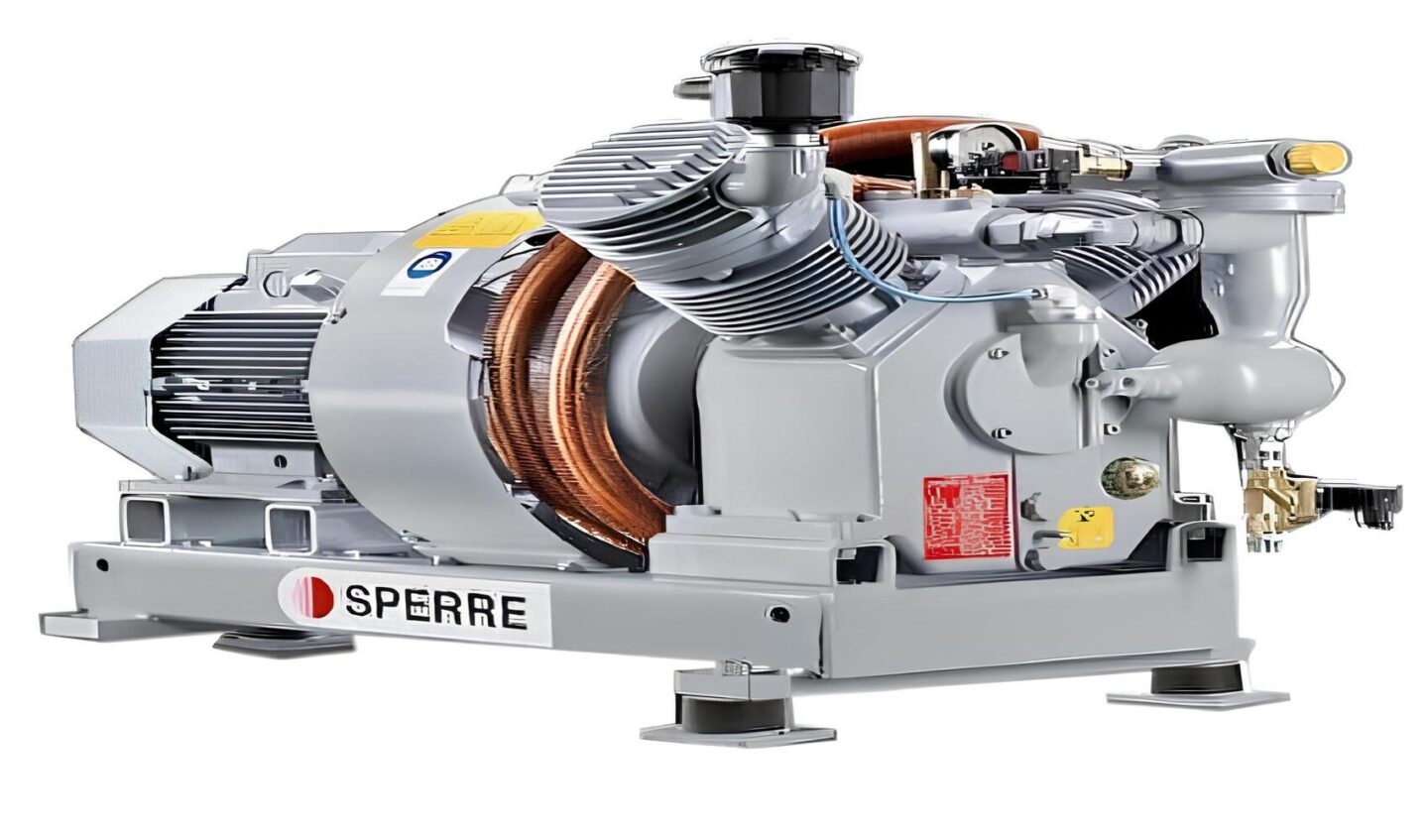

Understanding the Role of a Starting Air Compressor on a Ship

A starting air compressor is designed to generate high-pressure compressed air, which is stored in air receivers. When you start the engine, this air is released into the cylinders to rotate the engine until it fires on fuel. No air, no start.

In most marine and industrial applications, including power plants, a dependable compressed air supply is essential. These compressors are responsible for delivering starting air to the diesel engine, which then uses a starter valve mechanism to initiate motion. Air receivers are used to hold the compressed air at pressures as high as 30 to 40 bar, ready for instant release when needed.

Why Your Ship’s Air Compressor Might Not Start

When the compressor doesn’t start, there are several culprits to consider. The issue might be with the start command, low pressure in the system, a faulty valve, or even an electrical panel error. Sometimes the problem is with the solenoid or a blocked pipeline.

Manual versus automatic starting modes can behave differently when things go wrong. In automatic mode, failures are often linked to sensors or the control air signal. In manual mode, it might be an issue with the physical start switch or relay.

It Could Be the Pressure (Or Lack of It)

Pressure issues are among the most common problems. Marine compressors are designed to work at high pressures, typically around 30 to 40 bar. If the air receivers don’t maintain this minimum pressure, the engine starter won’t activate.

Low discharge pressure could be due to air leaks, clogged filters, or the unit not reaching its full load capacity. If the compressor stops under load, you may have a malfunctioning pressure switch or a faulty stop mechanism. Regular pressure monitoring is key.

Temperature and Moisture Can Mess Things Up Too

Thermal conditions along with moisture content from the environment determine the functioning status of compressors. Water-cooled compressors need continuous access to cool fresh water in order to prevent overheating. Assembly area ventilation issues will negatively affect air-cooled units due to their reliance on external air flow.

Moisture buildup inside the system can damage internal parts and reduce efficiency. In compact facilities, poor drainage or humidity control can accelerate this. Always check that drainage valves are working and that air dryers are functional.

Troubleshooting Tips: How to Get Your Starting Air Compressor Running Again

Start with a step-by-step check. Make sure the compressor motor is receiving power and that the electrical panel shows no alarms. Confirm that the starter is engaged and not jammed.

Inspect the valves—especially non-return and control valves. A stuck valve can prevent air from reaching the engine. If everything checks out mechanically, look at your control signals and solenoid performance.

Using preventive maintenance as a friend for your system provides the best results. System reliability and operational efficiency improve when regular inspections lead to immediate part replacements. Thorough troubleshooting takes place frequently together with proper documentation of all observations for future reference needs.

When to Call K-Marine for Help with Your Starting Air System

At K-Marine, we understand how vital a dependable starting air system is for any vessel. Our engineers have hands-on experience with all sizes and types of marine air compressors. Whether it’s a compact unit for a small vessel or a complex assembly for a commercial ship, we’ve seen it all.

If your troubleshooting leads to dead ends, we’re here to offer high-performance solutions backed by technical expertise. Our goal is always to restore your system’s reliability and ensure your marine applications run without a hitch.

Conclusion: Keep Your Vessel Ready to Start Every Time

The starting air compressor turns out to be the concealed reason why ships fail to start. Addressing conditions and performing effective maintenance checks allows users to prevent waste of time and financial resources.

Regular maintenance of your system along with pressure and temperature checks should be followed up by prompt professional assistance if needed. Your ship needs to be operable whenever you put your key in the ignition.