You use hydraulic pumps on a daily basis when operating a marine ship. Such systems are used in steering, winch, crane and numerous other functions that are important. The failure of a hydraulic pump is immediately succeeded by downtime. Repairs are expensive, time is lost on schedules, and safety concerns increase. The good news is simple. The correct checks and habits can help you avoid most of the problems.

You will find in this manual how hydraulic pumps work, which are the most common on ships, and which are the most significant checks that can guarantee them to be in good condition.

Understanding How a Hydraulic Pump Works on a Vessel

A system is pumped with some hydraulic fluid. The pump rotates, thus forming a flow and pressure. That force is converted into a useful force by that pressure. You apply that force to lift, push or turn heavy equipment on board.

All hydraulic pumps require clean liquid, efficient seals and constant pressure. Each component would fail, and the entire circuit would perform a similar action. This is the reason why you must know what your pump is, and how it acts under load.

Common Marine Hydraulic Pump Types You Should Know

Various types of pump designs are utilised in marine systems. Both kinds of pumps are applicable to other jobs and pressure requirements.

Gear Pump Basics

A gear pump involves the use of meshing gears to drive fluid. Two external gear wheels are used in external gear pumps, and they turn in tandem. Internal gear pumps use an internal gear and an external gear inside the same housing.

You’ll see gear pumps often because they handle steady pressure well and offer a simple design. Many vessels rely on a wide range of hydraulic gear pumps for deck machinery. Gerotor pumps also fall under this group. These gerotor pumps use a compact internal gear design and work well in tight spaces.

Vane Pump Applications

A vane pump uses sliding vanes that rotate inside a housing. These pumps handle smooth flow and lower noise. You’ll often find vane pumps in systems that need steady pressure without sharp spikes.

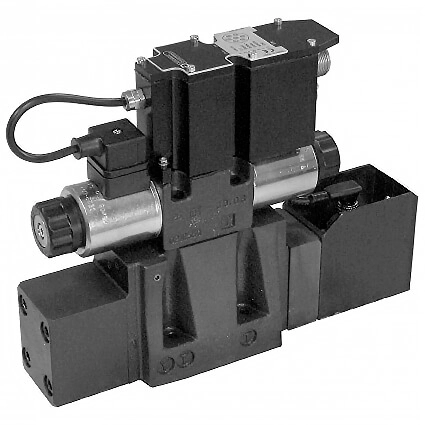

Piston Pump Variations

Piston pumps are used with heavier loads and high pressure, while the axial piston pump aligns the pistons to the drive shaft. A bent-axis design is used to tilt the pistons to produce more power. Then, pistons of a radial piston pump are mounted around a central shaft.

Many of these pumps use variable displacement. A variable displacement pump adjusts output based on demand. This feature helps control flow and pressure while reducing wear.

Key Hydraulic Pump Checks That Reduce Downtime

Periodic checks eliminate minor issues that would result in massive failures. You don’t need complex tools. You just need consistency.

Monitor Flow and Pressure Regularly

Always watch flow and pressure readings. Sudden drops or spikes tell you something changed. High-pressure seals and gears. Low pressure reduces power and control. When you press controls and feel delays, check readings right away.

Inspect the Pump Inlet and Seals

The pump inlet needs clean and steady fluid. Air leaks at the inlet cause noise and damage. Worn seal parts allow fluid leaks and pressure loss. You should inspect seals often and replace them before failure.

Check Lubrication and Internal Wear

Gears and pistons are ensured with proper lubrication. Lubrication is not provided well, and thus the metal parts grind during rotation. As time passes, gear teeth become worn off and decrease displacement. Also, don’t forget to check the quality of oil as well as its levels.

Review the Hydraulic Circuit

A healthy pump still fails if the circuit has issues. Blocked lines, dirty filters, or faulty valves restrict flow. These problems force the pump to work harder and raise pressure. Always inspect the whole circuit, not just the pump.

Early Warning Signs of Hydraulic Pump Problems

Your system gives you signs before failure. You just need to spot them early.

Listen for a strange noise when the pump runs. Feel vibration through controls. Watch for slow response or pressure loss. Check fluid for foam or heat. These signs point to inlet issues, worn gear surfaces, or failing seals.

Different pump designs show different symptoms. Gerotor pumps may lose smooth flow. Vane pump systems may struggle under load. A variable displacement pump may fail to adjust output.

Why Preventive Maintenance Beats Emergency Repairs

Emergency repairs are expensive compared to routine maintenance. They prevent any sudden closures on your part. You protect key parts like internal gear sets, external gear units, and piston assemblies. You also extend pump life and protect other hydraulic components.

Regular care keeps systems stable and safe. It also assists in planning service work rather than responding to the breakdowns.

Keep Your Hydraulic Pumps Running When It Matters Most

Hydraulic pumps make your vessel move. Basic checks of pressure, flow, seals, lubrication, and circuits count. Being consistent makes you minimise downtime and enhance safety.In case you require expert assistance, we are on the spot. K-Marine operates with marine hydraulic systems daily. We maintain gear pumps, vane pumps, axial piston pump systems, radial piston pump systems, etc. When you desire the predictability of good performance and minimal surprises, come talk to us and maintain your hydraulic pumps in good condition.