Why Smooth Marine Operations Depend on the Right Hydraulic Motor

In a well-functioning marine craft, there are all kinds of machines that operate in unison to lift, load and tie heavy contents. Among them, there is a real workhorse marine deck crane. It can be anything like hoisting the cargo, lifting the lifeboats, or operating equipment; deck cranes are necessary to promote safe and seamless operations at sea.

These cranes operate on the hydraulic motor, which is the deck crane hydraulic motor, and this is a powerful but small component that facilitates the key movements such as lifting, luffing, slew and hoisting. This is not a component, but a mechanical motion that makes precision handling and vessel efficiency fuel. In this posting, we will guide you on how it functions, why it is vital, and how businesses such as K-Marine ensure these motors are doing their best.

Understanding the Role of a Deck Crane Hydraulic Motor

Consider a hydraulic motor as a muscle which drives a limb. By analogy with how your biceps allow you to raise a box, the hydraulic motor transforms the fluid pressure into mechanical energy that makes arm cranes and winches move.

The hydraulic system in the crane of marine applications is on a closed-loop circuit. The pressure used in the system is controlled as hydraulic fluid is pumped in through the system to travel through different parts and generate the rotational force. This energy is used to provide constant, smooth slewing, hoisting and luffing functions of the crane.

The motor will have to be readily responsive to control commands to have slow and careful lifts, as well as fast re-positioning during loading. This level of control is what makes the hydraulic motor such an essential component in the working of the crane, particularly in the marine environment, where there is no such thing as unreliability.

Key Components That Make It All Work

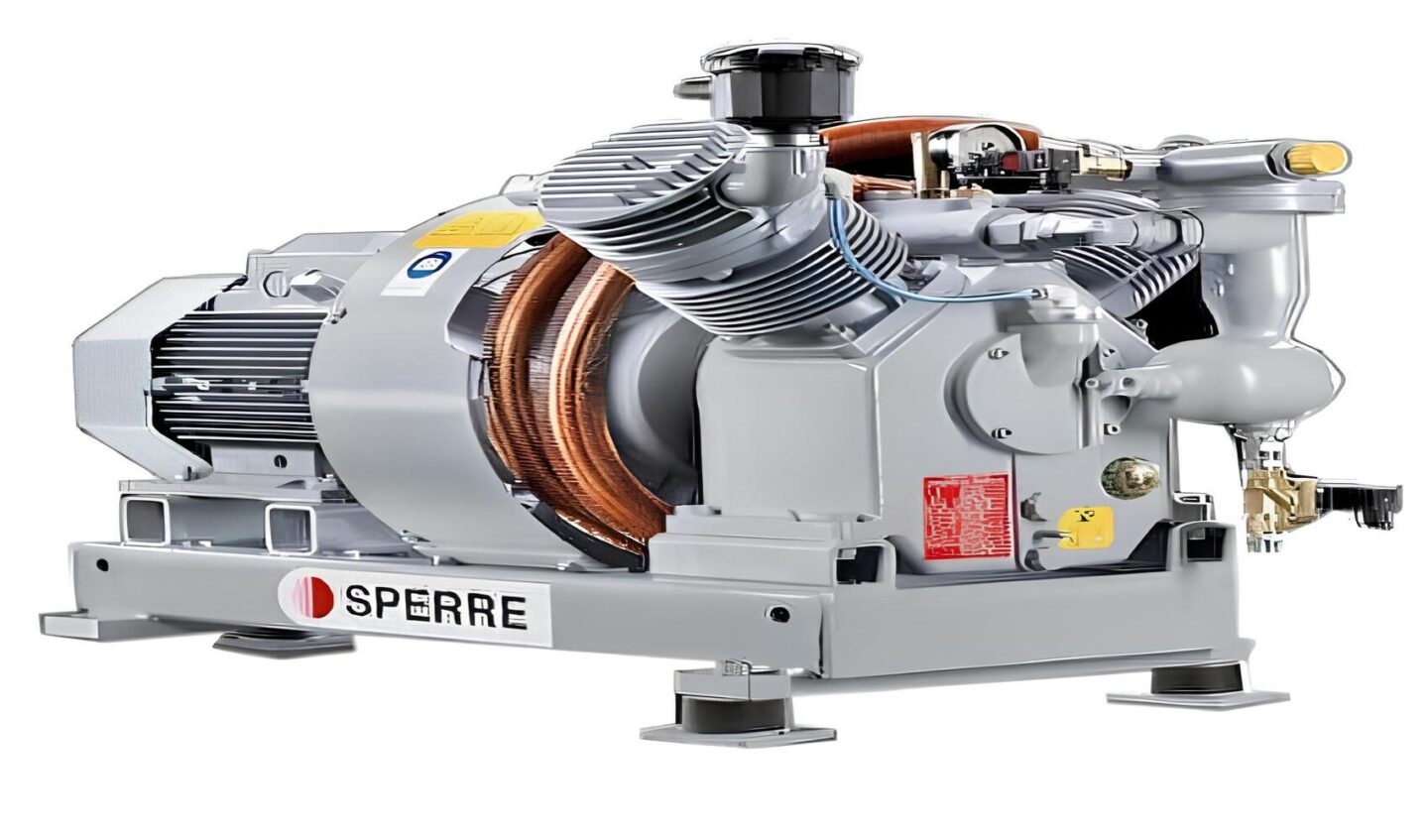

A hydraulic system does not operate on its own. It relies on a variety of combined elements, which have a particular responsibility of providing a smooth and firm crane operation. What are the significant components? Let us break them down:

- Hydraulic Pumps: These pumps pressurise the hydraulic fluid, acting as the system’s heart. Without the correct pressure, the system can’t function.

- Pistons: These convert fluid energy into mechanical force. Pistons are key to moving loads and are sensitive to wear and condition.

- Valves: These control fluid flow and direction. Faulty valves can cause jerky or stalled operations.

- Brakes: The safety-sensitive components used to stop or hold the movements of cranes. A defective brake may create a danger, particularly in the case of a heavy lift.

- Hydraulic Motors: These convert hydraulic energy into motion. The crane cannot hoist, slew, or luff without a trustworthy hydraulic motor.

All the parts must be in harmony, and maintenance is vital to safe operations in varying marine conditions.

Why Choosing the Right Model Matters

Not every motor or every hydraulic system is swept off the shelf the same. Devising the right model for your crane can significantly affect its efficiency and durability.

A motor with the correct pressure rating, size, and rotation capacity makes the product suitable for the crane’s use and weight demands. Mismatch of specifications can lead to poor performance in terms of slow speeds, overheating or breakdown entirely.

And this is why selecting a quality deck crane hydraulic solution is important. No matter whether you require a standard replacement with something more tailored to your needs, the product must best fit into your marine application.

Common Hydraulic Motor Issues and Maintenance Tips

Even the best systems encounter problems over time. Some common issues with deck crane hydraulic motors include:

- Low hydraulic pressure

- Fluid leaks

- Overheating

- Brake failure

- Unusual noise or vibration during hoisting or luffing

Regular inspection of the system’s condition is to be carried out to avoid costly breakdowns. Get alerts such as effective deceleration, too much noise, or unstable control-reaction.

By offering routine maintenance services for vessels, inspection, and replacement of parts, K-Marine assists vessel operators in maintaining their systems in their prime condition. Their approach focuses on long-term reliability because failure is not an option at sea.

How K-Marine Provides the Right Hydraulic Solutions

They say that when it comes to sourcing the right deck crane hydraulic motor, K-Marine is not just a supplier; we are a strategy partner. Regardless of whether a total renewal, a new product, or a trustworthy spare part, K-Marine offers customised solutions to your vessel’s specific configuration.

K-Marine has a broad and compatible support for its motors and parts, ensuring quality and durability. Our skilled workforce will always be with the clients, determining demands, suggesting any replacements, and ensuring that any system upgrade that will make the marine business run smoothly takes place.

The ability to integrate comprehensive marine expertise with a support network of responsive individuals makes our company reliable in the realm of marine hydraulic systems.

Final Thoughts: Keep Your Marine Operations Running High and Tight

Every smooth lift at sea starts with a hardworking hydraulic motor doing its job behind the scenes. From hoisting heavy cargo to fine luffing movements, your deck crane hydraulic motor is central to the ship’s daily rhythm.

If your marine equipment needs an upgrade or you’re seeking expert guidance, turn to K-Marine. As a reliable supplier, we provide top-tier parts, expert service, and hydraulic solutions that keep your marine operations running safely and efficiently, wave after wave.