The lifting and hoisting of your ship is supported by a deck crane hydraulic motor. Your deck crane will not be able to lift cargo safely and efficiently without a well-functioning motor, which can hinder the operation of your entire vessel. When you have observed a decreased hoisting capacity, a strange sound or a slow rotation of your deck crane, then you know that you must check your hydraulic motor. We will deconstruct some of the most frequent problems that you may encounter and explain how awareness can ensure that your marine operations are free from issues.

1. Hydraulic Pump Failures

One frequent issue with the deck crane hydraulic motors is the failure of the hydraulic pump. The motor is driven with hydraulic fluid forced by the pump. In case it is torn or broken, the crane loses its power. You may experience a decrease in lifting force or slower hoist speed. Minor leaks or damaged pistons may cause the pump to be less effective, resulting in additional stress on the other components. The maintenance ensures that the pump operates safely and efficiently by maintaining the proper pressure.

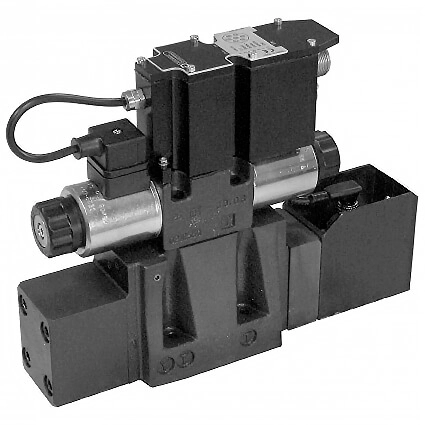

2. Valve and Control Malfunctions

The deck crane and hydraulic motor are steered using valves and control systems. When one of the valves is stuck, or a control part fails, the hoist will either jiggle, not spin evenly or not pick up loads. Hydraulic control issues may also lead to slow responses from the deck crane, which can impact cargo management and overall functionality. Having your valves and controls serviced and calibrated on a regular basis will ensure that your deck crane’s hydraulic motor does not unexpectedly fail and that your controls are properly set up.

3. Bearing and Component Wear

Some of the key components in the deck crane hydraulic motors include bearings, pistons, cylinders, and gears. The parts are heavily loaded and rotate continuously; hence, they wear out over time. As bearings or pistons begin to fail, you may hear some unusual noises, feel vibration or receive reduced lifting efficiency. Periodic checking of these components also enables you to change the parts which are worn out before they lead to larger problems. Monitoring the health of your hydraulic system is essential to ensure that you can lift, hoist, and slew on your vessel without any difficulties.

4. Noise and Vibration Issues

Too much noise or vibration not only irritates the senses, but it is also an indicator that there is something wrong with your deck crane hydraulic motor. Vibrations may be caused by luffing, gearbox misalignment or ineffective hydraulic drive. The problems of the pump, cylinder, or hoist mechanism can also be indicated by noise. Respond to these issues early before your crane, hydraulic motor or other deck equipment deteriorates. Professional maintenance and regular repairs reduce the chances of parts breaking and ensure your marine operations run smoothly.

5. Maintenance and Replacement Challenges

One of the most significant hazards to hydraulic motors in deck cranes is neglecting maintenance. Even a well-built motor will not last without regular checks, replacement of spare parts, and lubrication. Late maintenance may impair the lift capacity, rotation and the general performance of your deck crane. Collaborating with a trusted supplier of spare parts, hydraulic pumps, and other components will help you resolve issues quickly. Quality parts with the correct warranty ensure that your hydraulic motor and crane are in optimal working condition.

Why K-Marine Is Your Go-To Supplier for Deck Crane Hydraulic Motors

At K-Marine, we specialise in the repair and maintenance of afloat ships, as well as deck machinery, including hydraulic motors. Our crew collaborates with ship owners, managers, and operators worldwide. We do repairs in our workshop, on board vessels in Singapore, and in ports all over the world. We also offer riding squads on voyages in case of urgent matters.

Our specialisation is on quality, professionalism and customer satisfaction. Each project we undertake receives our complete attention, and we ensure that all repair or maintenance work meets the highest standards. Our employees have established a good reputation in the marine sector, where they provide comprehensive services in engine room and deck machinery repairs, steel structural work, and pipe installations.

We also maintain a substantial inventory of parts and equipment to meet urgent needs, and our extensive supplier network ensures that you have access to replacement components when needed. It may be a hydraulic pump, valve, piston, or gearbox, but we have the appropriate parts to keep your deck crane hydraulic motor in fine condition.

Conclusion

Cargo handling in ships is very crucial and safe because of hydraulic motors in deck cranes. Performance can be influenced by hydraulic pump failures, valve problems, worn bearings, noise problems and inefficient maintenance. It is essential to be aware of these typical problems to ensure that your deck crane operates effectively, your hoisting activities are efficient, and your ship is on schedule.

And if you wish to maintain your deck crane’s hydraulic motor in optimum condition, we can assist you. We offer end-to-end maintenance, repair and replacement services of the deck crane hydraulic motors at K- Marine as a way of guaranteeing efficient and safe operation of your marine operations. Contact us to arrange an inspection or discuss your specific needs regarding your hydraulic motor.