Your selection of a hydraulic motor for a vessel extends beyond selecting maximum power specifications. Selecting a hydraulic motor requires achieving equal levels between performance and efficiency together with durability so your vessel functions properly. That’s where K-Marine comes in.

We provide marine-specific hydraulic motors across different sizes as reliable answers for your deck machinery and propulsion system requirements. We will analyse the most suitable options in this guide to help you select the correct hydraulic motor which suits your vessel.

Understanding the Types of Hydraulic Motors for Vessels

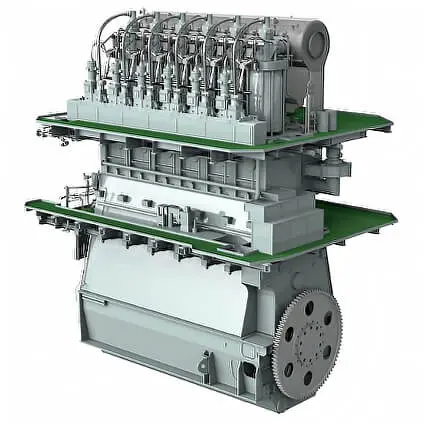

For proper recommendations one first needs to know about the various kinds of hydraulic motors that shipboard applications use.

- Gear motors: These devices offer a basic design with affordable costs which suits operations that need steady speeds. The meshing of gears allows hydraulic energy to become rotational energy.

- Piston motors: Rotational movement from piston motors occurs through the use of multiple pistons which operate efficiently at high pressure. Marine applications that need accurate and powerful operation commonly demand piston motors due to their characteristics.

- Vane motors: The hydraulic motors achieve mechanical motion conversion through rotating vanes. The size of these motors fits small systems while their functionality performs best under usual pressure ranges.

Each type of hydraulic motor has strengths that make it suitable for specific vessel functions, from operating a winch to powering propulsion systems. Knowing the differences helps narrow down your options.

Key Factors to Consider When Choosing a Hydraulic Motor

When selecting a hydraulic motor, these are the essential factors to consider:

- Torque requirements: The amount of rotational force required by your application determines its needs. High torque requirements exist for winches as well as heavy-duty deck machinery.

- Rotational speed: Different applications necessitate motors that operate at either high speed or low speed combined with strong torque capability.

- Displacement: This measures the volume of hydraulic fluid used per rotation. Larger displacement typically means more power output.

- Pressure rating: Higher-pressure motors can handle more demanding tasks without losing efficiency.

- Hydraulic fluid compatibility: Make sure the motor works with the hydraulic fluid used in your system.

- Type of motor: Depending on your vessel’s setup, you may need an axial piston motor, radial piston motor, or gear motor.

Choosing the right combination of these factors ensures your hydraulic system runs smoothly and efficiently.

K-Marine’s Top Hydraulic Motors for Marine Vessels

This summary includes a list of five best-performing K-Marine hydraulic motors that simplify your decision process. These motors provide marine environments with the engineered reliability combined with efficiency and operational durability.

1. BREVINI H1CR 55

The BREVINI H1CR 55 provides marine operations with a compact and flexible piston motor equipped to perform variable displacement operations at high rotational speeds. The motor satisfies both winch system and auxiliary equipment power requirements for efficient operations.

This compact piston motor can operate demanding tasks while maintaining peak efficiency because it delivers 770Nm torque and achieves 4,500rpm rotation speed maximum. The motor functions within a displacement range of 108cm³ under a pressure rating of 350 bar to succeed in demanding high-pressure marine conditions.

2. KAWASAKI SB510

The KAWASAKI SB510 represents a high-performance piston motor which provides consistent dependable power functions throughout marine hydraulic systems of varied applications. This hydraulic motor shows special performance in integrated deck elements as well as winches and various auxiliary mechanisms which need precise torque maintenance and dependable speed adjustment.

The motor produces 970Nm as its maximum torque force which allows it to handle robust loads and its speed reaches 1,000rpm. The 250cm³ maximum displacement maintains adequate hydraulic flow for strong motor performance as its 250 bar pressure rating allows it to handle medium-high pressure systems on vessels.

3. MITSUBISHI RMC350A

The MITSUBISHI RMC350A provides adequate power and durability to address demanding maritime operations for big vessels. High torque operation is possible with the heavy-duty hydraulic motor through a torque range up to 12.65kN/m which enables large-scale equipment and propulsion systems.

The rotational speed limit of this motor stands at 195min-1 to deliver its primary function of producing high torque output at low speeds which suits heavy-duty applications. This motor provides top performance due to its 3,507cm³ displacement capacity per revolution along with its powerful 24.5MPa operating pressure capability.

4. REXROTH A6VM107

The REXROTH A6VM107 serves as a trusted axial piston motor that functions with high precision and advanced pressure capabilities for state-of-the-art hydraulic systems used on contemporary ships. This hydraulic component stands out in demanding control systems requiring high efficiency including propulsion devices and specialised deck equipment systems.

The motor provides users with 681Nm of maximum torque along with a rotational speed range between 3,550rpm and maximum speed. Its maximum displacement range reaches 107cm³ and its pressure tolerance expands to 400 bar which allows reliable operation in high-pressure hydraulic systems.

5. KAWASAKI SB508

Low-speed high-torque demands drive the application of the KAWASAKI SB508 hydraulic motor which performs efficiently as deck equipment and hydraulic winch devices. Although it maintains a compact size the KAWASAKI SB508 delivers sufficient torque output of 465Nm to control heavy loads even in constrained areas.

Its capability to rotate at 1,300rpm strikes the equilibrium between power output and performance while its displacement plate covers up to 1,510cm³ to accommodate bigger hydraulic flow applications. The SB508 operates reliably as a 250 bar-rated solution designed to serve various vessels which need space-efficient hydraulic systems.

Why Choose K-Marine for Your Vessel’s Hydraulic Motors?

K-Marine recognises that boats require distinct requirements for their operations. Our company provides customers with a broad selection of hydraulic motors and pumps alongside necessary hydraulic system components. The marine environment causes no problems as our products remain firmly operational throughout numerous journeys.

Our personnel who have specialised in marine hydraulics over many years can help you select a proper hydraulic motor that meets your boat’s technical specifications as well as operational requirements.

Conclusion

Your vessel depends on selecting an appropriate hydraulic motor to operate efficiently and maintain smooth operations. An informed selection of hydraulic motors for your vessel requires understanding motor types combined with torque and displacement calculation and evaluation of our top recommendations.

K-Marine provides complete hydraulic motor option selections together with expert advice for your selection needs. Learn all K-Marine’s hydraulic motors alongside marine solutions by visiting our website.